Pontoon anchoring and pontoon mooring systems are essential for ensuring stability, safety, and durability of floating structures. There are three main ways to anchor pontoons:

Chain anchoring with concrete anchors

Pile anchoring with mooring piles

Anchoring with mooring diagonals

Single-module pontoons (such as a swimming pontoon or ECO swimming pontoon) can be installed without anchors. However, pontoons with several modules must always be anchored.

Because anchors are heavy, installing them requires special technology for safety. If you are considering a DIY installation, please contact us first via the form at the bottom of the page for advice on whether and how you should proceed.

Pontoon anchoring

Pontoon anchoring ensures that the floating structure remains secure in varying water conditions. The correct anchoring method depends on water depth, bottom type, climate, and the pontoon’s size. In Nordic conditions, the most common method is chain anchoring with concrete anchors, but pile anchoring and diagonal mooring are also used in specific situations.

Pontoon mooring systems

Pontoon mooring systems include all the equipment and techniques needed to keep pontoons stable. These can range from heavy-duty concrete anchors and chains to mooring anchors, mooring piles, or diagonal cables. Each system has advantages depending on the location: chain anchoring offers flexibility, pile anchoring is rigid but secure in warm climates, and diagonal mooring works in tight spaces near the shore.

Pontoon anchoring systems – Chain anchoring

In the Nordic ice conditions, the cheapest and most popular pontoon anchoring system is a combination of concrete anchors and mooring chains. Only a sufficient water depth (1 m) and the right chain length (five times the water depth) are required.

Chain anchoring is designed for securing the vessel horizontally, while retaining its ability to move up and down with water. Mooring anchors are designed as self-anchoring, and their mounting loops and reinforced concrete are resistant to seawater and strong impacts from rocks and ice.

The size and quantity of anchors are selected based on the type of substrate and the size of the pontoon. You can increase the anchor’s force by adding extra weights that are attached to the middle of the chain.

Technical specifications

| Extra weight/ anchor | Dimensions (mm) | Mounting loops / mooring chain (mm) | Typical use |

| 50 kg extra weight | 400 x 400 x 175 | 13 | As extra weight on boat pontoon |

| 200 kg extra weight | 600 x 600 x 310 | 13 | As extra weight on timber pontoons with concrete floats |

| 500 kg anchor | 900 x 900 x 270 | 16 / 13–16 | Anchor for swimming pontoon, boat pontoon and 40 l and 60 l mooring buoy |

| 1,000 kg anchor | 1000 x 1200 x 360 | 2 x 18 / 16 | Anchor for a boat pontoon, timber pontoons with concrete floats, and for 60 l and 120 l mooring buoy |

| 2,000 kg anchor | 1200 x 2000 x 36 | 2 x 22 / 16–20 | Anchor for a, heavy duty pontoons timber pontoons with concrete floats and a 120 l mooring buoy |

- Also read the post: “Floating Pontoon – DIY or Buy a Ready-Made Solution”

Floating pontoon anchoring (Pile and diagonal mooring)

Pile anchoring

The pile anchoring can be successfully used in pontoons that are parallel to the shore and are located at low depths (max 2 m) and have a soft bottom.

Pile mooring is a very secure fastening option, but due to its rigid fixation, there is a great risk that ice will damage the floating pontoon and shifts the piles from their place. For this reason, the use of pile mooring is most common in southern Europe and other permanently warm areas.

In the Nordic countries, the piles must be dismantled every autumn and the pontoon has to be lifted out of the water. In the spring, the piles have to be installed again – this is the only way to prevent damage to the posts by ice.

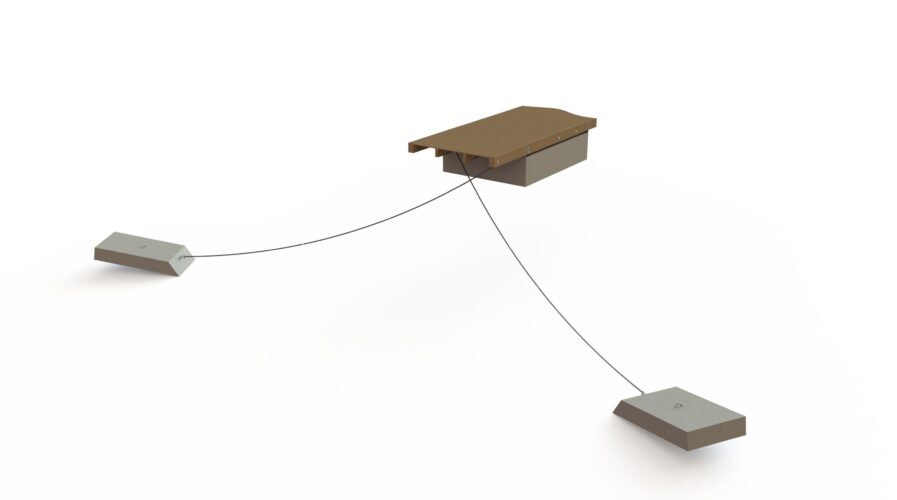

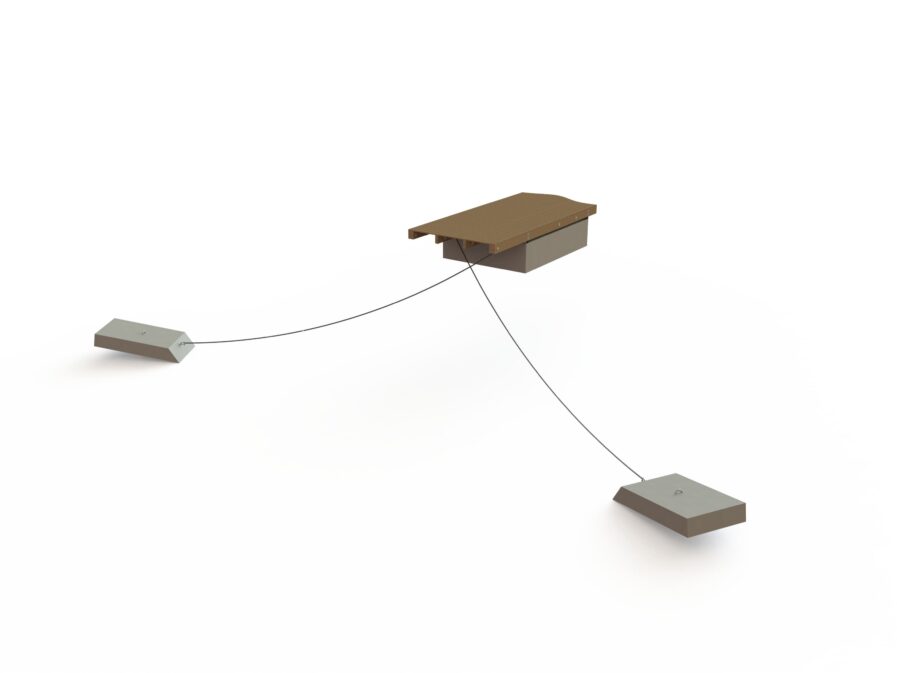

Diagonal mooring

Diagonal mooring is used rarely, and only in exceptional circumstances when the pontoon is very close to the shore and there is no room for chain mooring. This method carries a higher risk of ice damage in winter, and the fastening connections tend to rumble and squeak when moving around in waves.

- Plan your pontoon project: Assemble your own floating pontoon solution in our web application and instantly see the cost. [User guide here].

- For designers: Download mooring anchor and product models from the ProdLib catalog, with a step-by-step guide available.